WheatBP NEW

CerealsDB home WheatBP home FAQs Contact us

Wheat evolution Wheat development Wheat farming Milling Baking and brewing Wheat research SNPs SNP discovery

Our publications Related Web-sites

Milling

Early history - quern stones

Milling is the process by which cereal grains are ground into flour. Traditionally, and in some parts of the world to this day, this would have been accomplished by grinding the grain between two stones, a lower, stationary stone called the quern stone and an upper, mobile stone called the handstone. The oldest known flour milling devices are saddle stones (see main image). A saddle stone is a cradle-shaped piece of hard stone which holds the grain. The handstone would have been either a cylindrical piece of stone (held in both hands and drawn across the grain rather like a rolling pin) or a disc with a with a vertical handle on its back (rather like an upside-down mushroom) held in one hand. These hand stones were used to crush the grain and produced a rather coarse flour. In order to make grinding easier, the grain was often maltedCereal grains, such as barley and wheat, that have been made to germinate by soaking in water and then have their germination halted by drying in hot air are refered to as malted. before being used. More advanced cultures invented rotary querns. These operate in a similar manner to modern millstones and consist of two circular stones, a rotating runnerstone overlying a static bedstone. The grain enters the quern through a hole in the centre of the runnerstone and migrates to the edge as it is ground, emerging from between the stones as a coarsely ground flour. Such rotary querns are hand-powered and as a consequence are limited in size and milling capacity by the strength of their operator. However, they could be much heavier than the handstone used with saddle querns and so could be used with unmalted grain and produce a finer flour. An example of an early British quern is on display at the British Museum. Obviously, such methods are both laborious and time intensive. In addition, they produce only enough ground or cracked grain for a household or extended family.

Mills and mill stones

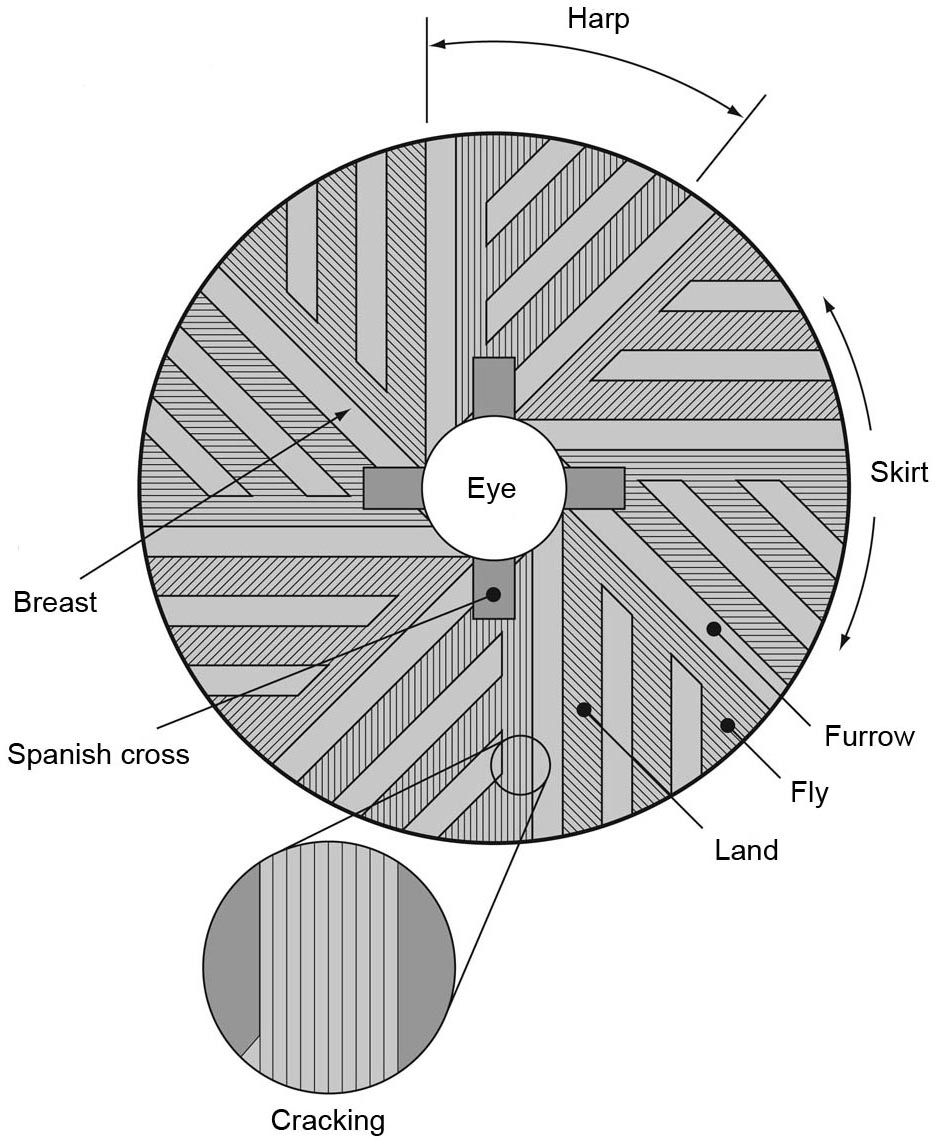

Figure 1. Diagram to show the anatomy of a millstone.

As the agricultural production of wheat grew and settled populations became larger there would have been the need for more efficient methods of flour production. Powered mills would have provided this step forward and these were common by Roman times. Much larger circular-shaped stones would be used in such mills and these produce a finer flour than that produced by hand held instruments. A great diversity of power sources have been used to drive the rotating action of the runnerstone. Initially, these large stones would have been turned by animals or slaves. With time, water or wind became the source of power to turn the millstone. Modern flour mills that use rotating millstones are often driven by electric motors. Perhaps counter-intuitively, millstones do not touch when in operation. There is a gap between the static bedstone and rotating runnerstone which is determined by the size of the grain. Grain is fed from a chute into a hole, known as the eye, in the centre of the runnerstone (Figure 1). An intricate system of groves known as furrows distribute the grain across the millstone surface, and also serve to ventilate and cool the millstones. The grinding surfaces of the millstones are known as lands and are divided into areas called harps (see accompanying diagram). Once ground the flour passes along narrow groves called cracking, and is expelled from the edge of the millstones.

Roller mills

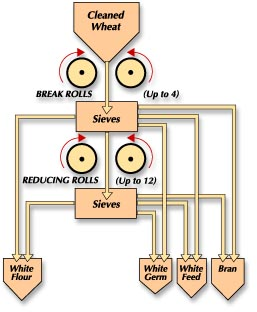

As populations expanded and the demand for more and better flour and bread grew, so a new milling process was devised. Originating in Hungary in the late 1870ís, this new process involved passing the grain between sets of spinning metal rollers. These mills operate by passing the grain between a series of paired counter-rotating rollers with fluted surfaces. The resulting crushed grain is sieved between each roller pair in order to separate the bran (coarse and brown in colour - see image below) from the starchy endosperm (fine and white in colour - see image below). The end product is a super-fine white flour. To produce wholemeal flour from this type of milling it is necessary to collect the bran that have been sieved off during the early stages of milling and add them back to the final product. To obtain a brown flour a proportion only of the extracted material is added back.

Figure 2. Diagram to show the basic layout of a roller mill.

Early roller mills were driven by steam engines, while modern examples are powered by electric motors. These mills are not only faster than traditional mills, they also produce a greater quantity of white flour of a higher quality. However, because of their higher speeds and more vigorous action there is a lot more damage done to the components of the flour. There are ways to reduce the damage and maintain a greater level of natural nutrients and milling technology is evolving to reduce the pressures and temperatures within the rolls. On the other hand, the fluted surface of roller mills breaks up starch molecules and giving the resulting flour a greater capacity to absorb water, ideal for the Chorleywood bread making process.

Flour can also be separated into its major components, gluten (protein) and starch. Wheat starch is used primarily as a thickening agent for soups, gravies, puddings, spreads and various other products. Gluten protein is often added to wheat flour to improve bread making quality, and it can also be used as a base for making various vegetarian foods.

Waste from milling is often used on agricultural land as fertiliser. Spreading is limited to once every five years, and is not applied to growing crops. Some milling waste has other uses: wheat bran is widely used as an animal feed, and wheat germ can be prepared and sold as a vitamin-rich health food.

More detail of the milling process and its history can be found on the web sites of Carrs Flour Mills and Doves Farm. A brief yet interesting introduction to the history of milling can be foundon the Shipton Mill web site.

Flour characteristics

Grain hardness is a quality expressed by wheat varieties to different extents. Hard wheat, which has a high protein content, is suitable for bread flours, while soft wheat, which contains less protein is better suited to foods with a shorter texture, such as pastry. The hardness of a grain is determined by the expression of a protein in the endosperm, a carbohydrate-rich material from which white flours are manufactured. Millers undertake the task of choosing and blending various grains to be milled into various flours. A protein linked to hardness, called friabilin, is associated with starch granules within the endosperm. Friabilin is a combination of two separate polypeptides, known as pin A and pin B. Whether a grain is soft or hard depends on a mutation in the gene which encodes the pin B protein. This mutation causes the instruction to encode the amino acid glycine to convert to an instruction to encode the amino acid serine. Those grains bearing the serine amino acid in the pinB protein tend to form harder wheat grains.

An important property of a milled wheat is the activity of an enzyme called alpha-amylase, an enzyme that breaks down starch resulting in poor qulaity flour. Both breeders and millers use the Hagberg Falling Number (HFN) to indirectly determine alpha amylase. The HFN test measures the number of seconds a plunger takes to fall through a mixture of wheat flour in water. The plunger will fall slowly if the mixture is thick with starch indicating low alpha amylase activity. conversely, it falls more rapidly if some starch has been converted to sugar through the action of the enzyme. Flour with a low HFN value will produce bread that is sticky and so clogs slicing machines. Such flour will be rejected by millers.

Flour treatment agents alter the appearance and properties of flours in order to better suit their intended purpose . For example, inspired by a fashion that arose in the 19th Century for whiter-than-white bread, bleaching agents such as chlorine are used to whiten flour (unbleached flour is has a pale cream colour). Oxidising agents such as phosphates and ascorbic acid are used to develop gluten in flour, enhancing its usability for products such as bread.

Potassium bromate is used as an oxidising agent which enhances gluten content. However, potassium bromate has been found to be carcinogenic and is banned in the UK and Europe. However, bromated flour is still widely used in the United States. The use of colours, sweeteners or other additives in UK flour is controlled by European Union legislation according to three separate directives published by the Food Standards Agency.

Types of flour

Most of us would describe "flour" as fine powder, made from wheat, which we use in cooking. However, depending on the wheat variety and the blending processes used by millers, different types of flour, each with a different purpose, are obtained. For example, there are flours intended for cake/biscuit making, for bread making, for household use, and for pasta production. The intended use of the various types of flour on sale is usually listed on the packet.

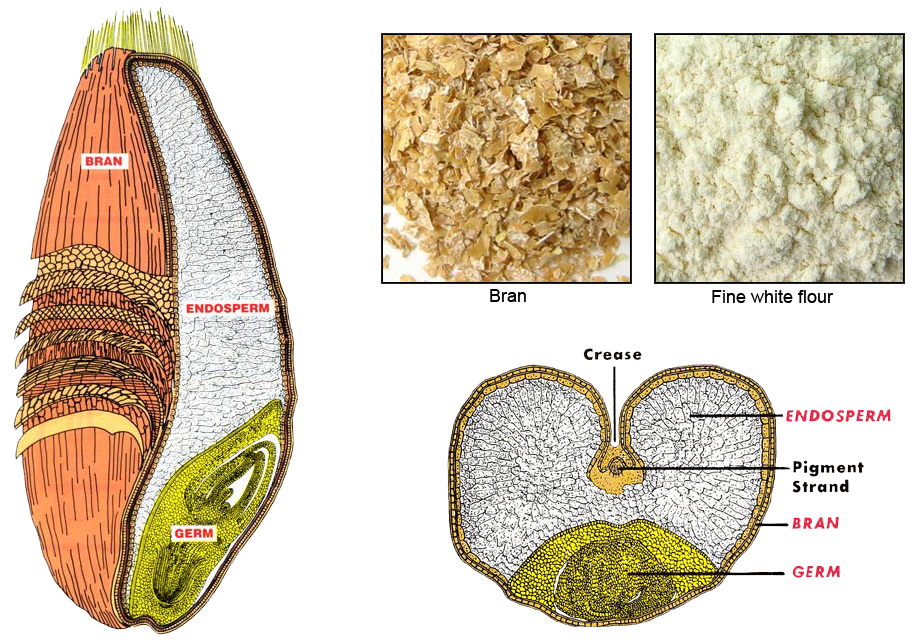

Figure 3. Diagram showing the parts of the wheat grain that produce different wheat types.

Wholemeal, white and brown flour

Wholemeal flour, as its name suggests, is flour made from the whole grain of the wheat, from which nothing is extracted and to which nothing is added; it contains all parts of the wheat grain including the outer layers of bran and the germ (see diagram). There is no difference between wholewheat and wholemeal flour, unless the packaging on wholemeal flour states that barley and/or rye have been added to the wheat. White flour, on the other hand, contains only the inner portion of the grain called the endosperm (see image). Unless the packaging explicitly states that the it is unbleached, the flour will have gone through a bleaching process; such bleached flour may be called refined flour. Flour that is referred to as 'Brown' is usually roller-milled, bleached flour to which caramel and sometimes some bran has been added.

80% - 90% extraction flours

Between 10% and 20% of the bran (the outside layer of the wheat) is sieved off to leave a finer, paler and lighter flour than 100% wholewheat. Provided it is labelled as stone ground, this is natural flour with only bran removed; it will not have been bleached or reconstituted. This type of flour is sometimes called wheatmeal and produces a loaf of a finer flavour and texture than wholewheat.

Strong or bread making flour

The primary rule for producing a really good wheat loaf is to use strong bread flour, which is made from semi-hard wheat with a medium to high protein content. When water is mixed into the flour, two of the flour proteins combine to form gluten. The gluten forms a network that is able to stretch as the dough ferments and carbon dioxide gas is released. On baking this stretched gluten network sets to give the structure and texture of the bread. Although gluten is a present in all wheat in varying amounts, strong flour is needed to ensure that sufficient gluten is formed to produce bread of good volume and appearance.

Granary flour

This is a combination of 80% - 90% extraction flour and malted wheat or barley flour. Malted wheat or barley has been allowed to start to germinate, thus releasing some of the sugars locked up in the germ. The result is a bread that has a characteristic sweet nutty flavour, much favoured by many people. Beware additives to granary type flours. Unless the packaging states that it is stone ground wheatmeal with added malted grain, it is almost certain to be roller-milled flour with added caramel, bran, molasses and malt extract.

Flour for cakes and biscuits

What differentiates a bread flour from flour more suited to making cakes and biscuits, is the gluten content. The ideal flour for making most cakes and biscuits has a lower protein content than bread making flour and is milled from soft wheat varieties. The protein needed to form the structure of cakes and biscuits is not from the flour used but from other ingredients such as egg. Use of cake flour gives a tender soft product as the gluten in the flour does not contribute significantly to the cake structure. If flour that is too strong is used the resultant cakes will be tough and dry and biscuits will not spread out when baked.

Self-raising/Self-rising flours

Self-raisng flour was invented by Henry Jones and patented in 1845. It is made by combining soft, biscuit flours with chemical aerating agents such as baking powder. The flour and raising agents are sifted together many times to ensure even distribution and consistent product quality. The aerating agents in the flour produce lighter and softer baked products as a result of creating small gas bubbles and cause batters to rise when heated. Sef-raising flour is used in the baking of cakes, scones and suet pastry (e.g., dumplings)

Plain flour

Plain flour is a flour that does not have a leavening agent added to it. It is usually milled from soft wheat varieties with lower protein and gluten levels than bread wheat. It is an all purpose flour ideal for cooking where the flour must combine with other ingredients and where a short crumbly texture is required. It is used to make biscuits, shortcrust pastry and to thicken sauces.

Web sites of interest

UK millers are represented by the National Association of British and Irish Millers (NABIM), an organisation that assists millers to improve their competitiveness and reduce their environmental impact. The UK milling industry uses 5.7 million tonnes of wheat each year to manufacture 4.5 million tonnes of flour. Wheat accounts for approximately 80 to 85% of the UK milling industry. The European Flour Millers Association and the National Association of British and Irish Millers websites may be of interest.

The Flour Advisory Bureau web site is a good place to look for recipes for bread making and baking using wheat flour

Interesting and informative videos showing the milling and baking process can be found on youtube.