WheatBP NEW

CerealsDB home WheatBP home FAQs Contact us

Wheat evolution Wheat development Wheat farming Milling Baking and brewing Wheat research SNPs SNP discovery

Our publications Related Web-sites

Baking

Sixty percent of the wheat flour milled in the UK is used in bread manufacture. Annual flour consumption is estimated to be around 74 kg per person.

Commercially grown wheat varieties vary in their molecular composition, and the flours made from the grain will show corresponding differences in their suitability for various baked goods. A component of wheat that is of particular importance is gluten protein (although gluten is most often thought of with regard to wheat, it is also present in other cereal grains such as barley and rye). Hard wheats contain high levels of gluten, soft wheats contain relatively little. Some wheat varieties, such as Gallant and Solstice, are relatively high in gluten and contain as much as 12.5% gluten mass, making them suitable for manufacturingi goods that require a high protein content such as bread. High gluten content in wheat flour can be enhanced further using flour treatment agents. Other wheat varieties, such as Cocoon and Invicta, contain less gluten and are more suited to producing flours aimed at manufacturing goods with a shorter texture, such as biscuits and pastry. Varieties such as Beluga and Gravitas that have a very low gluten content are suited for the brewing and distilling industries.

Sixty percent of the wheat flour milled in the UK is used in bread manufacture. Annual flour consumption is estimated to be around 74 kg per person.

Commercially grown wheat varieties vary in their molecular composition, and the flours made from the grain will show corresponding differences in their suitability for various baked goods. A component of wheat that is of particular importance is gluten protein (although gluten is most often thought of with regard to wheat, it is also present in other cereal grains such as barley and rye). Hard wheats contain high levels of gluten, soft wheats contain relatively little. Some wheat varieties, such as Gallant and Solstice, are relatively high in gluten and contain as much as 12.5% gluten mass, making them suitable for manufacturingi goods that require a high protein content such as bread. High gluten content in wheat flour can be enhanced further using flour treatment agents. Other wheat varieties, such as Cocoon and Invicta, contain less gluten and are more suited to producing flours aimed at manufacturing goods with a shorter texture, such as biscuits and pastry. Varieties such as Beluga and Gravitas that have a very low gluten content are suited for the brewing and distilling industries.

Bread is a staple food with 99% of households in the UK buying bread - this is equivalent to 12 million loaves sold every day. prepared by cooking a dough of flour and water and often additional ingredients. Doughs are usually baked, but in some cuisines breads are steamed (e.g., mantou), fried (e.g., puri), or baked on an unoiled skillet (e.g., tortillas). It may be leavened or unleavened, but in the UK the typical loaf of bread is leavened. Salt, fat and leavening agents such as yeast and baking soda are common ingredients, though bread may contain other ingredients, such as milk, egg, sugar, spice, fruit (such as raisins), vegetables (such as onion), nuts (such as walnuts) or seeds (such as poppy). Bread has been prepared for at least 30,000 years. The development of leavened bread can probably also be traced to prehistoric times.

Wheat flour, in addition to its starch, contains three water-soluble protein groups (albumin, globulin, and proteoses) and two water-insoluble protein groups (glutenin and gliadin). When flour is mixed with water, the water-soluble proteins dissolve, leaving the glutenin and gliadin to form the structure of the resulting bread. When relatively dry dough is worked by kneading, or wet dough is allowed to rise for several hours (perhaps overnight), the glutenin forms strands of long, thin, chainlike molecules, while the shorter gliadin forms bridges between the strands of glutenin. The resulting networks of strands produced by these two proteins are known as gluten.

Leavening

Leavening is the process of adding gas to a dough before or during baking to produce a lighter, more easily chewed loaf of bread. This process may be achieved either chemically or through the use of yeast:Chemical

A simple technique for leavening bread is the use of gas-producing chemicals. There are two common methods. The first is to use baking powder or a self-rising flour that includes baking powder. The second is to include an acidic ingredient such as buttermilk and add baking soda; the reaction of the acid with the soda produces gas.

Chemically leavened breads are called quick breads and soda breads. This method is commonly used to make muffins, pancakes, American-style biscuits, and sweet breads such as banana bread.

Yeast

Many breads are leavened by yeast. The yeast used for leavening bread is Saccharomyces cerevisiae, the same species used for brewing alcoholic beverages. This yeast ferments carbohydrates in the flour, including any sugar, producing carbon dioxide. Most bakers in the U.S. leaven their dough with commercially produced baker's yeast. Baker's yeast has the advantage of producing uniform, quick, and reliable results, because it is obtained from a pure culture. Many artisan bakers produce their own yeast by preparing a growth culture which they then use in the making of bread. When this culture is kept in the right conditions, it will continue to grow and provide leavening for many years.

Both the baker's yeast and the sourdough method of baking bread follow the same pattern. Water is mixed with flour, salt and the leavening agent (baker's yeast or sourdough starter). The mixed dough is then allowed to rise one or more times (a longer rising time results in more flavor, so bakers often "punch down" the dough and let it rise again), then loaves are formed, and (after an optional final rising time) the bread is baked in an oven.

Many breads are made from a "straight dough", which means that all of the ingredients are combined in one step, and the dough is baked after the rising time. Alternatively, dough can be made using a "pre-ferment", when the leavening is combined with some of the flour and water a day or so ahead of baking and allowed to ferment overnight. On the day of the baking, the rest of the ingredients are added, and the rest of the process is the same as that for straight dough. This produces a more flavorful bread with better texture. Many bakers see the starter method as a compromise between the highly reliable results of baker's yeast and the flavor and complexity of a longer fermentation. It also allows the baker to use only a minimal amount of baker's yeast, which was scarce and expensive when it first became available.

Flour contains many chain-like proteins that are insoluble in water. When these become wet as water is mixed with the flour these proteins link up end-to-end creating an extensive interconnected network of coiled proteins, the glute. The glutinous dough is both plastic and elastic; it will change its shape under pressure but moves back towards its original shape when the pressure is removed. This allows the dough to expand as carbon dioxide released by the yeast is trapped to form bubbles; the glutenins in the walls of the bubbles will be resitant enough to prevent them bursting and the trapped gas will give the bread dough its characteristic spongy structure. This gluten network can be stronger or weaker depending on the ingredients (such as the type of flour) and how you work the dough. Glutens are a family of proteins with a range of molecular structures. Of particular importance is glutenin, which has distinctive elastic properties that give wheat flours their various characteristics and determines their suitability for different baked goods. Glutenin is made up of long chains of interlinked subunits. These form so-called ‘loop and train’ structures that are in equilibrium with one another. If glutenin is stretched, the number of loop and train structures falls out of equilibrium, storing energy until the stress is released and they can return back to their former orientation. For more information on the milling and properties of flour, please go to our section on milling.

When I watch the dough expand I see it as a lively white cushion, growing bigger and bigger, blowing up very slowly with thousands of tiny balloons inside. As much as 80% of the volume of bread is empty space. The bubbles interrupt the network of gluten and starch granules, dividing it into millions of very thin sheets that form the bubble walls. The carbon dioxide produced by the yeast diffuses into any tiny bubbles it encounters and enlarges them. Thus, the more bubbles produced during the preparation of a dough, the finer and more tender the resulting bread. Yeast cannot be rushed, it must be given time. When the Israelites fled Egypt they could not tarry – they could not waste the time required for yeast to work. Their bread had not risen and so was eaten, and is eaten to this day in memory, unleavened. The end of this period (the proving period) is signalled by a doubling of dough volume. To check that the bread has finished proving you could follow the advice of an Russian cookery book published in 1860 and place the loaf in a bucket of water. When the loaf has sufficiently risen it will rise to the top of the bucket. Or, less courageously, you could poke the dough with your finger. If it does not spring back this means that the gluten network has been stretched to the limit of its elasticity and the dough is ready. 4. Again, knead on a lightly floured surface but this time only briefly to homogenise any remaining yeast and the air pockets that have formed 5. Shape into loafs, place in buttered tins and leave to prove for 30 minutes; 6. Bake in a preheated oven at 220C for 35-40 minutes. Baking is the process of turning all the beautiful work you have done into a delicately chambered, crisp loaf. As the dough heats up it becomes more fluid and the gas cells expand and the dough rises (called oven spring). The main cause of oven spring is the vaporisation of alcohol and water into gases. These fill holes in the gluten network and expand the dough by as much as half its initial volume. The oven spring stops when the crust becomes stiff and firm enough to resist and when the interior of the loaf reaches 70-80C. This is the temperature at which gluten proteins form strong cross-links and water-laden starch granules swell and set. At this point the yeast has already died and the series of transformations from grain to bread are almost complete. Now the walls can no longer stretch and so the gas pressure in the holes builds, eventually popping the walls and creating the familiar open network you see when you slice a loaf. Legend has it that you know the loaf is finished if you hear a hollow sound when you tap the base. This means the inside is light and fluffy. More scientifically you can check with a thermometer that the centre is at just less than 100C.Breads make from non-wheat flour tend to be much denser than traditional bread .

.

Traditional bread making is a lengthy process. Bread flour is mixed with water and sugar to produce a stiff dough. Recipes vary, some of them including fats that soften and preserve the structure of the dough whilst cooking. The dough is then kneaded, which develops gluten and gives bread dough a suitable structure. The dough is then allowed to rise, the yeast feeding on the sugars in the recipe and producing bubbles of gas that cause the dough to rise. After a first rising, the dough is kneaded again, a process called ‘knocking back’. Finally the bread dough is allowed to rise again ( a process known as proofing) in the pan in which the bread will be baked. A detailed explanation of the breadmaking process can be found on the Allotment.org website.

In 1961, the invention of the Chorleywood Bread Process greatly increased the efficiency of bread making, and British bread remains amongst the cheapest in the world. The UK branded bread market is worth approximately £2.9 billion, and some bread manufacturers are striving to bake bread from 100% British-grown wheat. The Chorleywood Bread Process allowed the production of usable bread dough from the low-protein flours produced in the UK. The flour is mixed with hard animal or vegetable fats, large amounts of yeast and salt. The quantity of yeast is high in order to produce sufficient volume of gas bubbles in the bread to make it rise rapidly. The resulting loaf has very little flavour so salt is added in an attempt to compensate for this. Hard animal or vegetable fats are used to support the bread structure, as without it the bread dough would collapse. A Chorleywood Bread Process loaf contains around a third of its mass in water, a quantity that has increased in recent years. The bread dough must be mixed with large quantities of preservative to inhibit moulds that would thrive in such moist conditions. The completed dough is then kneaded using high-energy mixing machines to develop gluten, then proofed and baked within 3 hours.

Use of the chorleywood Bread Process has become controversial in recent years with public concerns about food quality and nutrition. The Chorleywood Bread Process is blamed by some for the rise in number of sufferers of yeast intolerance. The Bakers Federation website has a positive outlook, while promoters of home-made produce, such as Allotment.org, are more critical. The ongoing Real Bread Campaign is opposed to the Chorleywood Bread Process.

Supermarket bread is rarely crusty because it tends to be under-baked; this leaves more water in the loaf, allowing less flour to be used to produce a loaf of the same weight.

Not all bread is leavened using cultivated bakers yeast. Sourdough is leavened using a natural blend of wild yeast and bacteria cultured from the grain. A baker that makes sourdough bread may have an initial starter culture, a semi-liquid dough that contains the leavening microbes, from which a samle is taken and added to the loaf. Cultures are sustained by adding flour and water to the mixture, and may last indefinitely. Established bakers manufacturing sourdough bread may have used the same sourdough culture for half a century or more. More information on sourdough breadmaking can be found on the John Downes Bakers website.

While the majority of bread in Western cultures is baked, alternative methods of cooking are used in China and other parts of South East Asia. Mantou is a breadmaking tradition from Northern China, where wheat is grown as a staple crop instead of rice. Mantou bread is steamed rather than baked, having a very soft, moist consistency, and is sometimes also fried to make a popular dessert.

Traditionally pasta is manufactured using hard wheat such as durum. The highest quality pasta is made from durum wheat semolina and eggs, while cheaper pasta excludes eggs from the recipe. The very cheapest pasta mixes high economy soft wheat with durum wheat. Hard wheat flours with high gluten protein content are used so that pasta does not loose its shape or disintegrate as it absorbs water during cooking. The proteins serve as an insoluble mesh which contains the starch granules as they become bloated with water. Industrially manufactured pasta dough is exposed to a vacuum in order to remove any air bubbles that may exist before it is extruded into shape. Extrusion machines knead the dough to a uniform consistency using augers that then force the dough through shaped nozzles.

Seitan is a meat replacement product manufactured from wheat. Manufacturing seitan is an ancient practice devised by Buddhist monks seeking to supplement their strictly vegetarian diet. Seitan is made by mixing strong wheat flour with water to form a stiff dough that is then kneaded in cold water. The cold water is changed frequently, taking away starch from the dough and leaving a sticky mass of gluten behind. This is cooked and can take on a very meat-like texture, but its flavour is lacking and needs to be marinated or seasone, usually with soy sauce, in order to make it more appetising.

Seitan is a meat replacement product manufactured from wheat. Manufacturing seitan is an ancient practice devised by Buddhist monks seeking to supplement their strictly vegetarian diet. Seitan is made by mixing strong wheat flour with water to form a stiff dough that is then kneaded in cold water. The cold water is changed frequently, taking away starch from the dough and leaving a sticky mass of gluten behind. This is cooked and can take on a very meat-like texture, but its flavour is lacking and needs to be marinated or seasone, usually with soy sauce, in order to make it more appetising.

Those seeking to use seitan and other wheat-based protein sources face a setback in that glutens do not contain all the essential amino acids used to construct animal proteins. The amino acids that are deicient can be obtained by eating beans and pluses such as lentils. Nutrition-savvy vegetarians and vegans need to consider this when choosing what to eat.

Wheat germ is derived from the embryonic plant inside a whole wheat grain, often sold as a by-product from manufacturing white flours. Wheat germ is a very rich source of vitamins, minerals and fibre and is now being marketed as a health food. Wheat germ oil is used by some vegetarians as an alternative to cod liver oil, being rich in omega 3 fatty acids. These fatty acids are thought to be protective against heart disease, lower cholesterol in the blood, and beneficial effects on the immune and endocrine systems. The amount of omega 3 relative to omega 6 is believed to have an effect on brain function.

Despite its name, buckwheat is not related to wheat and, indeed, belongs to a separate taxonomic group. Buckwheat is a dicot (wheat is a monocot) belonging to the family Polygonaceae, the knotweed family which contains dockweeds (you will probably know these as the large leaved plants that one uses, perhaps without effect, to calm nettle stings). However, its seed are used to make flour. While a rather obscure food crop in western cultures, buckwheat is widely consumed in China, Russia and Eastern Europe. Buckwheat contains rather more protein than true wheat and can be used to manufacture bread, but the protein in buckwheat flour is distinct from wheat gluten and thus can be consumed by people who suffer from wheat intolerance.

Despite its name, buckwheat is not related to wheat and, indeed, belongs to a separate taxonomic group. Buckwheat is a dicot (wheat is a monocot) belonging to the family Polygonaceae, the knotweed family which contains dockweeds (you will probably know these as the large leaved plants that one uses, perhaps without effect, to calm nettle stings). However, its seed are used to make flour. While a rather obscure food crop in western cultures, buckwheat is widely consumed in China, Russia and Eastern Europe. Buckwheat contains rather more protein than true wheat and can be used to manufacture bread, but the protein in buckwheat flour is distinct from wheat gluten and thus can be consumed by people who suffer from wheat intolerance.

Brewing

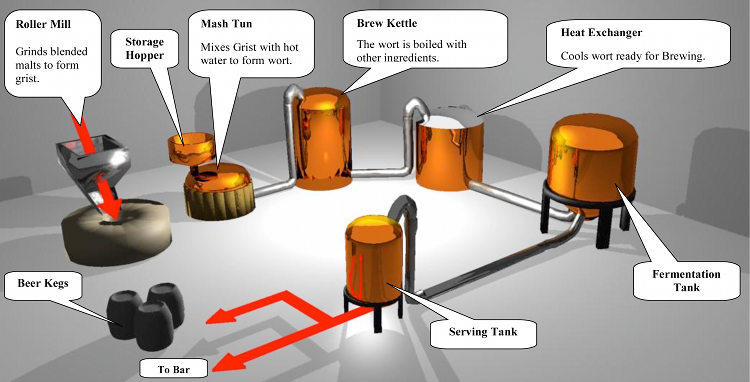

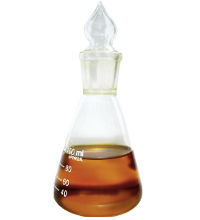

While the majority of beers are brewed from barley, there is a minority that are manufactured from wheat. Weissbier (a German word meaning ‘white beer’) which is so named becauseof its pale colour, originates from the South German province of Bavaria. It is made in a filtered clear form and also as Hefeweizen (see image), which is cloudy due to the remaining yeast (hefe is German for yeast). Witbier is another beer brewed from wheat originating from Belgium. A variety of yeasts, all of them single-celled fungi belonging to the genus Saccharomyces, are used to ferment wheat beers similar to those used to ferment beers derived from barley. Two forms of brewing yeast are used, named ‘top cropping’ and ‘bottom cropping’, indicating the depth at which they perform fermentation. Top cropping yeast is commonly Saccharomyces cerevisiae, the same species as baker’s yeast. More information on the cultivation and development of yeast strains can be found on the Cara Technology website.

While the majority of beers are brewed from barley, there is a minority that are manufactured from wheat. Weissbier (a German word meaning ‘white beer’) which is so named becauseof its pale colour, originates from the South German province of Bavaria. It is made in a filtered clear form and also as Hefeweizen (see image), which is cloudy due to the remaining yeast (hefe is German for yeast). Witbier is another beer brewed from wheat originating from Belgium. A variety of yeasts, all of them single-celled fungi belonging to the genus Saccharomyces, are used to ferment wheat beers similar to those used to ferment beers derived from barley. Two forms of brewing yeast are used, named ‘top cropping’ and ‘bottom cropping’, indicating the depth at which they perform fermentation. Top cropping yeast is commonly Saccharomyces cerevisiae, the same species as baker’s yeast. More information on the cultivation and development of yeast strains can be found on the Cara Technology website.

Lambic, also from Belgium, is brewed from wheat. Unlike most other beers it is not fermented using cultivated brewers yeast. Rather, manufacturers employ a technique known as spontaneous fermentation using wild yeasts growing on the grain. This technique gives the beer a pungent acidic flavour.

Wheat is now being used as an ingredient in industrially manufactured beers to enhance some physical properties. Brewing wheat that has been torrefied produces a beer with a thick head of foam that is stable for longer once served. Torrefied wheat is manufactured by heating wheat with steam under high pressure, then decreasing the pressure rapidly. Starch molecules within the grain flash and expand rapidly, producing a light fluffy appearance. A similar technique is used to manufacture popcorn and some breakfast cereals.

The Scotch Whisky Association states that to be classified as a true 'Scotch Whisky' it must be distilled from barley, but does not forbid the inclusion of other cereals into the recipe. Malted wheat is occasionally used as a whisky ingredient, and also as an additional ingredient to wheat beers and in some breads. More information on wheat malting can be found on the Maltsters Association of Great Britain's website. Wheat does have some limited uses in the distilling industry in the United States. Bourbon, a product of specifically American manufacture, is a whiskey that is brewed from approximately 70% corn. The remainder of the composition is made up of Barley and either wheat or rye. Bernheim, A novel American whiskey distilled from at least 51% wheat.

Wheat distillation is used in the UK to manufacture ethanol for use in biofuels. This is a controversial use of wheat as many cannot justify the use of a food crop to produce fuel. Somerset County Council coordinated the EU funded Bioethanol for Sustainable Transport Project, and Somerset county has one of the largest biofuel refineries in Europe. Although this project has ended details about bioethanol can be found on the BEST (Bioethanol for Sustainable Transport) web-site. Somerset County Council deploymed 41 road vehicles that were capable of running on fuel composed of variable quantities of bioethanol and hydrocarbon petrol. They published an information leaflet to detail the project to the public.